Too much work, too little time, too few staff – who does not know this problem? In addition, mental activities are frequently not really tangible; you have too many projects on the go at the same time and are only too easily dispersed. However, there are a few options for mastering this everyday chaos – one of them is Kanban. This article describes what Kanban is and how it can work. Our practical example: the living Kanban in the Infrastructure department of Porsche Informatik.

What is Kanban?

“Kanban” comes from the Japanese and consists of two words: KAN (visualize) and BAN (map, blackboard). That already almost says everything: Processes are displayed on a map (the Kanban board) by means of cards (so-called tickets). This process management system was developed around 1940 by the car manufacturer Toyota for production control. It significantly reduced throughput times in automotive production.

But what does it have to do with IT?

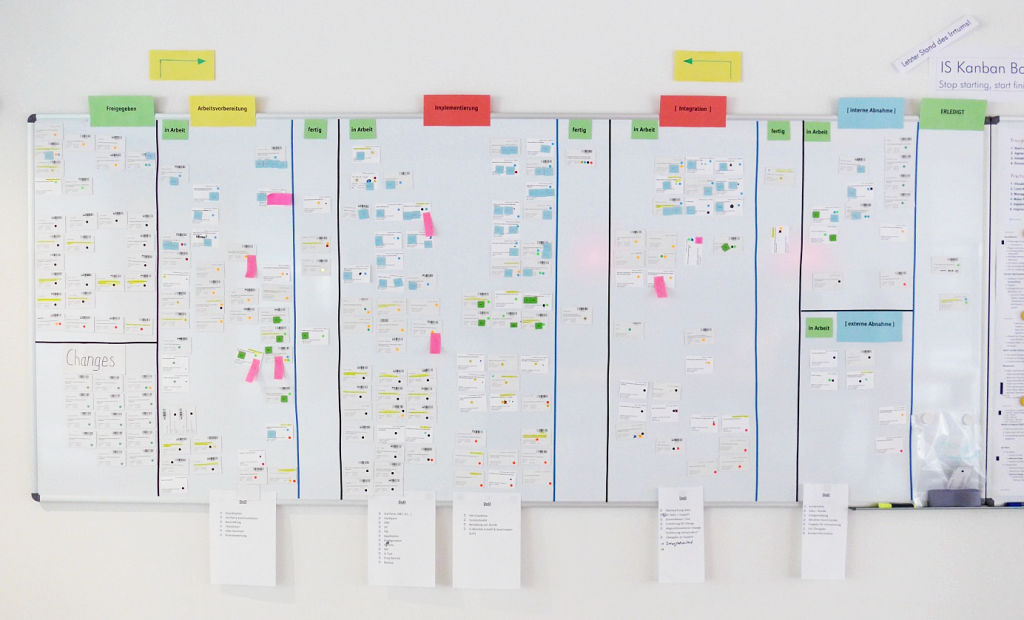

This is what a Kanban board looks like.

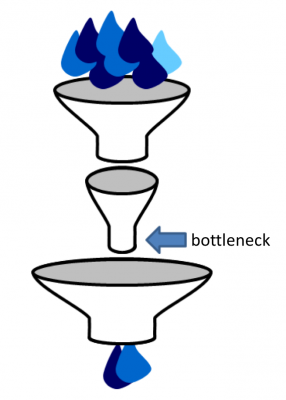

Kanban makes bottlenecks visible.

The core of Kanban, namely shortening throughput times, can be used wherever throughput times play a role. Activities without physical actions are usually difficult to represent; therefore it is also difficult to find bottlenecks there. With Kanban, all tasks are visually and tangibly displayed on a board: This means that everything that takes time to look at is displayed, making it easier to understand the entire process. Through the visualization, bottlenecks of activities and changes are much more visible than in applications, databases or Excel spreadsheets.

Don’t put more on your plate than you can handle.

An important principle of Kanban is “Limit the WIP” (Work in Progress). In other words, you only have to take on as many tasks as you can handle. By limiting the current work, there are less open projects at the same time. You can concentrate better on a smaller number of activities, thus reducing the throughput time. The bottleneck cannot so easily clog.

Kanban makes bottlenecks visible and reduces throughput time.

The principle of continuous change

Kanban does not mean discarding existing structures reinventing the wheel. Kanban helps to continually improve ongoing processes without interfering too much with organization. This evolutionary change management can be summarized in four basic rules:

- Start with what you are doing.

- Respect the existing processes, roles, responsibilities and hierarchies.

- Within these structures, make iterative small improvements everywhere.

- Promote leadership at all levels in the organization.

Sounds good – but does it work?

Kanban at Porsche Informatik

On the basis of the Kanban basic principles and our self-defined rules, we have defined and implemented our board design. To avoid falling into the usual trap – just sticking everything on the board – there are two input areas. All activities first land in a backlog pool before being released weekly by the backlog team. Release is based on the urgency and / or the scheduled date and also depends on the maximum load of the team. In this way, the volume of tasks and the resulting pressures are reduced in a targeted manner to a degree that can be managed by the team. Change requests must be on the board and are not released by the backlog team.

A major difference to the past is that we do the current work first and get new work only when resources are free again (pull instead of push). This sounds really logical, but unfortunately is not always implemented.

One thing at a time!

Each task (ticket) moves from the left to the right on the board and passes through the columns work preparation, implementation, optional integration, as well as internal or external acceptance until it is completed. This process – as analysis has demonstrated – practically suits all our activities.

The ticket contains, among other things, the job title, customer order or internal improvement, and has space for colour markings. Coloured dots represent the different teams involved in the ticket. Depending on the team, there are also markers for individual employees, as well as – most importantly – space for a blocker. This is clearly visible and contains brief information on why the ticket cannot be further processed, i.e. what exactly (an external cause outside the work domain) is blocking the ticket.

The tickets thus move from left to right, but processing is from right to left. Thus, a started job is ended before work is begun on a new job.

Thanks to this presentation, customers can be shown at any time not only that their topic is currently being worked on, but many others too. Equally, the Kanban board can be used to inform other teams, who can immediately see the status of a particular ticket.

At the Kanban Board, we maintain an overview: The grouping – based on the team points – is immediately noticeable and all tasks are clearly visible.

Always stay flexible.

The “Definitions of Done” (DoD) below the column make clear to everyone when a ticket moves to the next column. These definitions describing when a step is completed are self-imposed and can be challenged at any time. The Kanban rules are also defined in this way. Nothing is carved in stone and one of the rules reads: “Adjust rules continuously”. This happens in a monthly improvement meeting, in which everyone can participate. This especially deals with the points from the improvement board: where everyone can use cards to submit feedback on the current situation, suggestions for improvements to procedures or rules, or propose topics for discussion. After all, it is the human who brings Kanban to life and keeps it alive. The ideas, possibilities and criticisms from each individual define the board and how it is lived.

Express: When it’s really urgent.

The rules should be adhered to – only the express ticket can go ignore them, since it must be treated as a priority. It is visibly striking because it is attached to a red magnet. Such a ticket changes the definition from “Urgent” to “Really Urgent” and is only released by the Backlog team. Our current rules mean that there can only be one Express ticket on the board at a time as this can be a blocker for other tickets.

It this useful or can we get rid of it?

“And what has changed?” – A lot! Already within a few months after the first workshop a lot of positive things happened. Thanks to the daily meetings with all teams at the Kanban board, which last a maximum of 15 minutes, communication has improved significantly for cross-team work. What is currently being worked on has become much more visible and tangible for all. Problems are solved more quickly, unnecessary e-mail traffic is minimized and the workflows simply work more smoothly. The fact that employees who do not usually have anything to do with each other daily also meet strengthens the cohesion and is good for the group climate. This did not happen to the current extent before Kanban.

Here, any suggestions for improvement and open questions can be submitted.

What is the future of Kanban?

Everyone can ask themselves this question, because Kanban lives by everyone who is involved. The rules are changeable and the improvement pool is an integral part of the board.

Of course, we did not just introduce Kanban overnight, because Porsche Informatik is too large and complex. Kanban guru Klaus Leopold introduced us to the topic in workshops lasting several days – many thanks again!

All this did not just happen yesterday, but was implemented in early 2015. What has been going on with Kanban since then, what the current situation is, and whether we are still using Kanban at all, I will report in the second part. Stay tuned!